In today’s defense and security sectors, the demand for reliable ballistic protection is greater than ever. A key element in this protective ecosystem is bulletproof glass, an engineered material designed to withstand high-velocity threats while maintaining optical clarity. But how is bulletproof glass made, and what makes it such a critical component in safeguarding lives?

What Is Bulletproof Glass?

Also known as anti bullet or ballistic glass, bulletproof glass is a multilayered barrier that resists penetration from firearms. Contrary to its name, it isn’t entirely impenetrable, but rather highly resistant to bullets, especially when engineered for specific threat levels. Used widely in banks, military vehicles, embassies, and secured facilities, bulletproof glass plays an essential role in both public and military defense systems. In many tactical applications, it’s an integral part of defense providing both transparency and trusted protection.

The Materials Used in Bulletproof Glass

At its core, how bulletproof glass is made depends on the right mix of materials. Laminated glass forms the outer layers, providing rigidity, while layers of polycarbonate inside absorb shock and prevent spall. This combination allows the material to resist and slow incoming projectiles.

Additional elements like PVB (polyvinyl butyral), advanced interlayers, and adhesives are used to bond the structure together. These materials are not only chosen for strength but also for their ability to maintain visibility, making them ideal for glass for transportation, where both protection and field awareness are crucial.

Layering Techniques and Construction Process

Bulletproof glass is made by layering sheets of glass and polymer into a specific sequence. Once stacked, the layers are placed in an autoclave, where heat and pressure bond them into a single transparent panel. The result is a hybrid structure capable of absorbing and dispersing the energy from ballistic threats. This precise construction is what makes bulletproof glass effective in scenarios requiring mission-critical defense. It’s a prime example of how our custom glass manufacturing capabilities allow for exact tailoring of thickness, weight, and curvature, depending on the application.

How Is Bulletproof Glass Made for Different Threat Levels?

Different use cases demand different levels of ballistic resistance. For instance, glass used in mobile military units may require curvature and lighter weight, while static installations demand maximum impact absorption. To meet these needs, manufacturers follow international certifications such as NIJ, EN 1063, and STANAG standards. Before full-scale production, ballistic simulations are performed to predict how the glass will behave under various conditions thus ensuring optimal performance and safety. These standards also help differentiate between general-purpose glazing and specialized options offered by expert safety glass manufacturers in the defense industry.

Testing and Validation

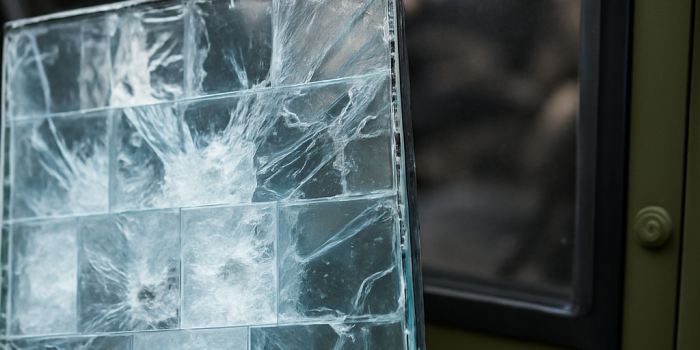

Every bulletproof glass window must prove its durability in real-world trials. Manufacturers test the glass against different calibers and impact angles to confirm multi-hit resistance and ensure no dangerous fragmentation occurs. These tests simulate extreme conditions such as rapid-fire and high-energy impacts to verify that the glass remains structurally sound. This rigorous validation is what separates industry-standard glazing from the solutions offered by top bullet proof glass manufacturers.

Customization in Defense Systems

Modern bulletproof glass manufacturing does not rely on one-size-fits-all solutions. Each bulletproof glass window can be customized for size, transparency, curvature, and frame compatibility. Even advanced features like embedded sensors, thermal coatings, and smart-tint technologies can be integrated.

Whether used in defense vehicles, watchtowers, or surveillance infrastructure, this tailored approach enables glass to meet very specific mission parameters—delivering the protection and functionality needed in high-risk zones.

Advancements in Bulletproof Glass Engineering

Understanding how bulletproof glass is made today involves recognizing decades of engineering advancements. From early composite panels to modern nanolayered structures, bulletproof glass has evolved into a highly customizable and effective security solution.

These innovations not only increase ballistic resistance but also reduce weight and enhance visibility, making them essential for high-performance military and transportation platforms alike.

More Than Just a Shield

Knowing how bulletproof glass is made offers deeper insight into the critical role it plays in modern defense. It’s not just a pane of reinforced glass, it’s a product of rigorous design, testing, and material science, engineered to protect lives in unpredictable environments.

From bank teller windows to battlefield vehicles, bulletproof glass remains an essential element of proactive security and advanced manufacturing.