Behind every reliable ballistic glazing system is a precise and highly controlled glass manufacturing process. For applications ranging from rail transportation to defense vehicles, the effectiveness of a protective solution depends not just on material quality, but on how it’s engineered, fabricated, and tested. OSG’s glass manufacturing process is handled in-house, from raw glass selection to lamination, framing, coating, and final inspection. This article offers a detailed look into how custom laminated and ballistic glass is produced, from the initial cutting to the final delivery.

Material Preparation

The glass manufacturing process begins with selecting materials that meet both structural and protective requirements. For ballistic glazing, these materials typically include flat glass, polymer interlayers (such as PVB or polyurethane), and optional transparent ceramics or composites for higher protection levels. Before fabrication begins, raw sheets are inspected, cleaned, and prepared for shaping.

Cutting and Shaping

Once materials are selected, glass sheets are cut using automated CNC machinery capable of handling both straight edges and complex geometries. In ballistic applications, accuracy is critical: small deviations can affect impact resistance and integration with framing systems. For applications requiring curved glass, such as locomotive windshields or vehicle hulls, precise forming techniques are used to ensure accuracy and optical clarity. Cold bending or hot forming is applied where curvature is required. The ability to shape glass while preserving structural performance is key in transportation and defense platforms, where form factors are often customized and load-bearing.

Lamination Process in Ballistic Glazing

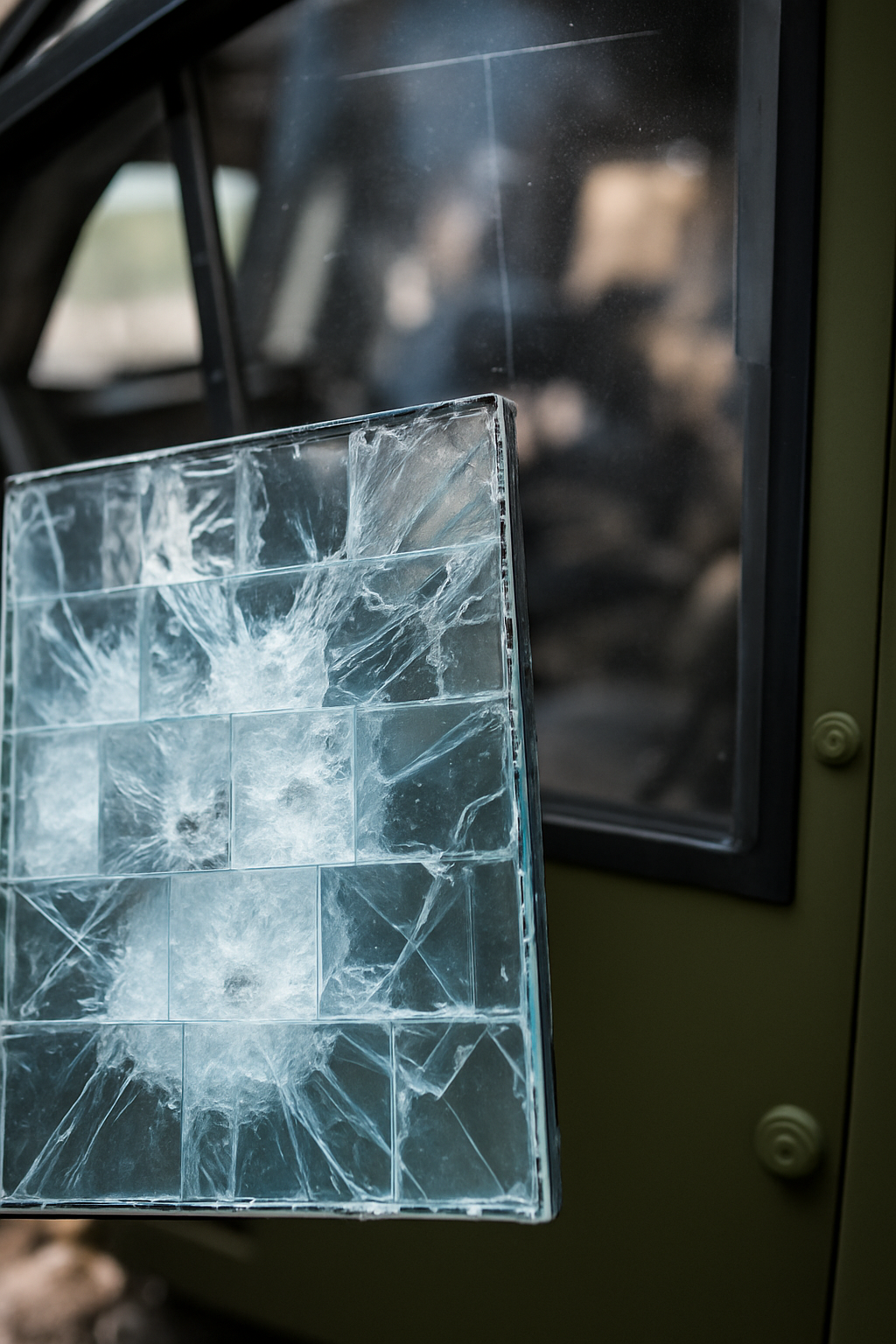

Lamination is a core step in producing ballistic glazing. During this phase, layers of glass and polymer interlayers are assembled into multi-ply stacks. These are then bonded together using heat and pressure, typically inside an autoclave, under tightly controlled temperature and vacuum conditions.

For enhanced performance, interlayers may include anti-spall films or embedded elements such as heating wires or switchable tinting. This ensures that the glass assembly not only resists penetration but also functions effectively in a range of environments.

Functional Integration

Beyond the glass itself, OSG integrates a wide range of features directly into the glass unit. These can include:

-

Embedded sensors or heating elements for defogging and de-icing

-

Light-control films or LCD layers

-

Laser scribing

This part of the glass manufacturing process is tightly coordinated with lamination and bonding to preserve clarity, alignment, and reliability. Integration is particularly important in ballistic glazing, where functional add-ons must not interfere with the material’s protective performance.

Framing and Sealing

OSG manufactures custom frames using steel, aluminum, or composite profiles, ensuring compatibility with the glass curvature, thickness, and load distribution. Each frame is engineered to support the glazing structurally and also accommodate mounting constraints, environmental exposure, and operational stress specific to its end use.

Once framed, the units are sealed using advanced bonding materials such as structural silicones and elastomeric seals. These create watertight, vibration-resistant joints that can withstand temperature shifts, mechanical stress, and long-term use. For ballistic glazing, this sealing step is critical as it prevents delamination, moisture ingress, and system fatigue.

Coating and Finishing

As the final step in the glass manufacturing process, coated finishes are applied to enhance both performance and durability. Anti-reflective coatings improve visibility, especially in high-glare environments, while hydrophobic layers reduce cleaning requirements and protect against environmental wear. Infrared and UV coatings are also added to manage heat gain and shield interior components from solar damage. These functional coatings are typically applied using vacuum deposition or screen printing techniques, which ensure even, durable coverage across each surface.

Testing and Quality Control

No glass manufacturing process for ballistic use is complete without rigorous testing. At OSG, every unit undergoes strict quality assurance protocols, including:

-

Optical inspection for clarity and distortion

-

Ballistic testing to international standards (NIJ, STANAG, ATPD)

-

Transportation safety standards for impact resistance and fire safety.

-

Environmental stress testing for thermal cycling, humidity, and UV exposure

This ensures that every glass unit delivered meets or exceeds performance thresholds for its intended operating environment.

Final Assembly and Delivery

Once validated, units move through final assembly, where gaskets, brackets, or mounting elements are added using careful techniques that ensure internal elements remain dust-free and functional.

Packaging is customized to protect finished products in transit, whether for local installation or international shipment. OSG’s flexible production capacity allows for both small-scale prototyping and large-scale production runs – all supported by regional logistics.

Conclusion: Why a Complete Glass Manufacturing Process Matters for Ballistic Glazing

The creation of high-performance ballistic glazing requires more than material selection. It depends on a fully integrated glass manufacturing process that considers design, performance, durability, and environment from start to finish. OSG is a trusted provider of advanced protection systems built on proven material performance and precision manufacturing. Our customized offerings are engineered to meet specific requirements across transportation, defense, and infrastructure applications.

Contact us to learn how we can support your next project with solutions tailored to your operational needs.