The Materials that Make Up Modern Ballistic Protection Systems

Modern transparent assemblies used in transportation, defense, and critical infrastructure are far more complex than a layer of clear glass. These systems must provide visibility while also offering protection, structural integrity, and long-term durability. Whether installed in railcars, military vehicles, or public buildings, transparent armor solutions must protect from threats and wear-and-tear such as ballistic impact, UV radiation, vibration, chemical exposure, and extreme temperatures. This reliability stems from the careful selection and integration of materials .Glass, polymers, ceramics, adhesives, frames, coatings, and seals each play a defined role, but it’s their integration that determines overall effectiveness. This article provides an overview of the protective and ballistic materials used in modern transparent designs and how they work together under demanding conditions

Laminated Glass: The Structural Core of Ballistic Assemblies

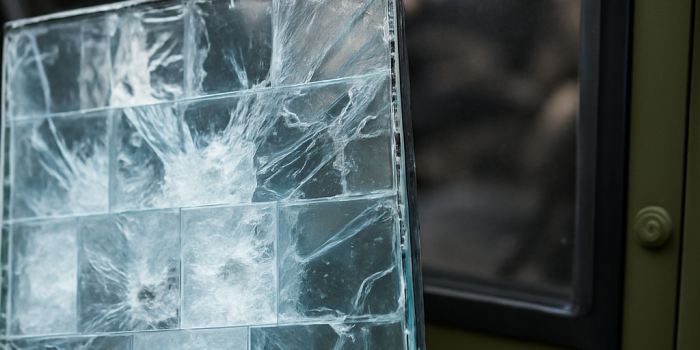

Laminated glass forms the backbone of transparent safety and ballistic protection systems. It consists of multiple layers of glass bonded with polymer interlayers, typically polyvinyl butyral (PVB), ethylene-vinyl acetate (EVA), or polyurethane formulations. These interlayers play a crucial role by absorbing impact energy, holding shattered glass in place, and minimizing penetration and spall.

In transportation and defense applications, laminated glass must balance optical clarity with mechanical performance. The thickness, number of layers, and interlayer composition are carefully tuned to meet specific threat levels, from anti-vandal to full ballistic protection. For example, multi-ply laminates used in rail applications are designed to resist flying debris across a wide temperature range. For bulletproof protection, more layers are added, and for special applications, laminates are coupled with additional functional layers, such as anti-fog films or low-emissivity coatings.

Ceramics and Composites: Ballistic Materials Without Bulk

To achieve higher protection levels without excessive weight, transparent ceramics and composite materials are often introduced into the layered glass stack. Materials like ALON (aluminum oxynitride) or spinel offer exceptional hardness and are transparent in the visible spectrum. These ceramics can stop high-velocity projectiles at a fraction of the thickness required by glass alone.

The back plane layers frequently incorporate lightweight composites or glass-reinforced polymers. These materials are engineered to absorb residual energy and provide structural support. For applications like armored vehicles or aircraft, where payload weight is critical, this combination of ceramics and composites enables superior protection with minimized bulk.

Coatings for Ballistic Clarity and Durability

Surface coatings are critical to the performance and longevity of transparent ballistic materials. Anti-reflective coatings improve visual clarity by reducing glare, particularly important in transportation cabins where safety relies on the operators’ clear vision. These coatings are often applied using vacuum deposition techniques, creating nanometer-thin, durable layers with precise optical properties.

Scratch-resistant and hydrophobic coatings protect the surface from abrasion and moisture infiltration. In outdoor or high-use environments, these help maintain transparency and reduce cleaning frequency. UV-blocking films preserve the integrity of the polymer interlayers and reduce heat buildup, while infrared-reflective coatings help control internal temperatures by reflecting solar energy.

Advanced protection systems may use multilayer stacks of coatings, each tailored to a specific function. These stacks are engineered for compatibility with the base substrate and the environmental conditions they will face, from desert heat to arctic cold.

Frames and Sealing Materials

A protective assembly is only as reliable as its supporting structure. Frames made from stainless steel, aluminum alloys, or high-strength composites must match the mechanical performance of the ballistic materials and remain stable across a wide range of conditions. Importantly, the thermal expansion behavior of the frame must align with that of the surrounding materials to prevent stress fractures or seal failure.

Sealing systems play an equally vital role. Elastomeric seals, silicones, and high-performance adhesives are used to maintain airtight and watertight bonds. They must withstand thermal cycling, UV exposure, and mechanical vibration without degrading. In mobile environments like rail or defense, where constant movement can stress joints, the selection and placement of seals are critical to long-term integrity.

Integrated Design: Engineering Ballistic Materials to Work Together

While each material has a defined function, high-performance protective systems are not simply layered like a sandwich. True performance emerges from the interaction of all elements, requiring a systems-based design approach. Engineering must account for how ballistic materials respond to impact, expand and contract with temperature, adhere under pressure, and maintain clarity over time.

This integrated approach is central to how OSG engineers its protective assemblies. Rather than treating seals, frames, and ballistic layers as modular components, they are co-designed to perform as a unified system. For example, thermal simulations are used to match expansion coefficients, while impact modelling ensures energy is distributed across both transparent and opaque layers. This allows for precise customization to meet regional regulations, environmental exposure, and threat levels.

Ballistic Materials Make the System

The effectiveness of transparent protective assemblies depends on the integration of the system. From laminated glass and transparent ceramics to coatings, composites, frames, and seals, each element contributes to the whole. As the demands on safety-critical systems grow, so must the understanding and application of these materials OSG is a trusted provider of advanced transparent protection systems, built on a foundation of proven ballistic material performance. Our customized offerings are engineered to meet specific requirements across transportation, military, security, and infrastructure applications.

Contact us to learn how we can support your next project.