Glazing systems used in defense applications operate in extreme and unpredictable environments. They are exposed to harsh climates, mechanical shock, vibration, dust, moisture, and direct hostile threats. In these conditions, multilayer glass must deliver reliable protection, maintain visibility, and preserve structural integrity under operational stress.

As a custom glass manufacturer, OSG develops multilayer glass systems specifically for defense platforms. Each system is engineered with a clear focus on protection, survivability, and mission reliability, ensuring consistent performance in demanding operational environments.

Multilayer Glass Engineered for Defense Protection

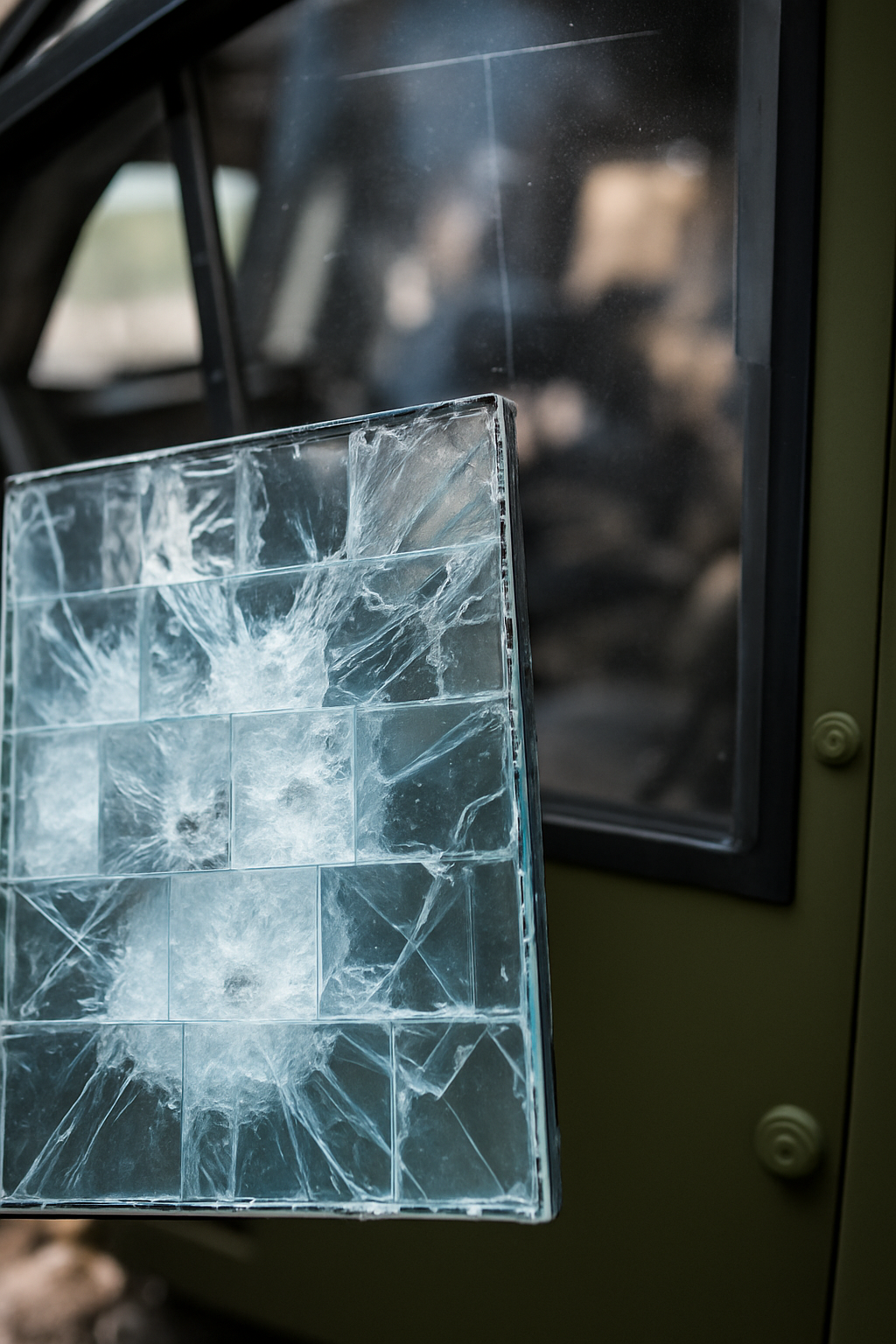

In defense applications, multilayer glass functions as a critical protection component. It is designed to mitigate threats, protect personnel, and integrate seamlessly into armored platforms and military systems.

Typical applications include:

- Armored land vehicles

- Naval and maritime defense platforms

- Military transport and support vehicles

- Observation, command, and surveillance systems

Multilayer glass is used for windscreens, side windows, crew compartments, and protected observation interfaces. Each application requires controlled optical performance, mechanical robustness, and engineered behavior under impact and extreme stress.

The engineering focus is on:

- Threat-oriented layer configuration

- Structural performance under impact and shock

- Controlled fracture and energy dissipation

- Compatibility with armored frames and protection systems

These systems are engineered for protection and survivability, rather than civil safety or comfort requirements.

System-Level Engineering for Operational Durability

Defense glazing systems must remain reliable throughout extended operational lifecycles, often in austere environments. Multilayer glass design therefore considers the entire system, not only the glass layers.

Advanced bonding technologies ensure layer stability under thermal cycling and mechanical shock. Sealing solutions protect against environmental ingress that could compromise performance over time. Robust framing and integration methods maintain structural alignment and optical performance under operational loads.

Material selection accounts for long-term aging, ensuring that interlayers, adhesives, and coatings retain performance characteristics throughout deployment cycles.

Manufacturing Foundations That Support Mission Reliability

High-performance multilayer glass production for defense relies on controlled manufacturing processes and strict quality standards. Precise dimensional control, repeatable layer assembly, and rigorous inspection ensure that each system performs as designed.

This approach supports:

- Consistent protection performance

- Predictable optical behavior

- Structural reliability under operational stress

- Reduced maintenance during deployment

Operational feedback from defense platforms informs continuous refinement of multilayer glass systems, supporting evolving mission requirements.

Conclusion: Multilayer Glass Built for Defense Protection

Multilayer glass systems for defense are engineered to perform in real operational conditions where protection and reliability are mission-critical. By focusing on survivability, structural integrity, and long-term performance, OSG delivers glazing solutions that defense operators can rely on in demanding environments.

The result is multilayer glass engineered for defense applications—providing protection-focused performance, operational durability, and dependable functionality throughout the system’s service life.